In the sea of safety regulations and guidelines, navigating the waters of OSHA’s confined space rules might feel like finding your way through a labyrinth. However, understanding whether a permit is required for a confined space is not an insurmountable challenge. All it requires is a clear definition of what constitutes a confined space and an analysis of the specific risk factors involved.

Understanding Confined Spaces

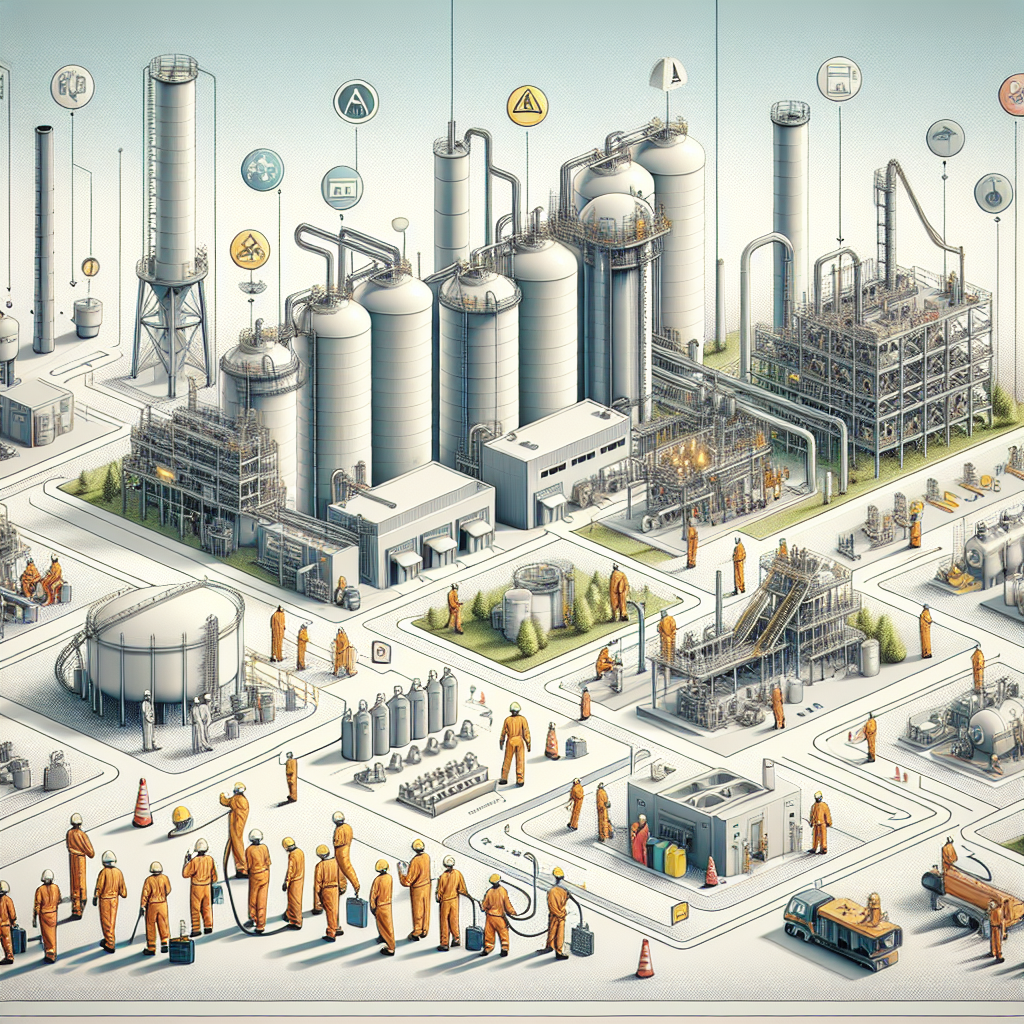

Picturing a confined space might evoke images of a narrow tunnel or a tiny storage closet. However, according to OSHA standards, a confined space is essentially any area of the workplace that’s large enough for a worker to enter, suitable only for limited periods of work and has restricted entries and exits. Think of it as a cubby hole that’s not quite designed for continuous occupancy – a storage tank, silo, vat, or pipeline, for example. Recognizing such places is vital for worker safety and compliance with safety regulations.

Identifying Permit-Required Confined Spaces

Not all confined spaces are created equal. Indeed, some carry more risks than others. Imagine an old, musty wine vat with the lingering fumes of fermented grapes – this presents a serious risk of hazardous atmosphere. Or consider a grain storage bin which might engulf an unfortunate entrant in an avalanche of corn kernels. Think even about a greased chute with a downward-sloping, tapered floor – a true trap in the making. All these examples represent permit-required confined spaces due to their dangerous characteristics.

Requirements for Entry into Permit-Required Confined Spaces

If you’re planning to venture into a permit-required confined space, you’ll need your armor of safety protocols. These typically include obtaining a Confined Space Entry Permit – the “magic portal key” to the space – and initial steps like purging, ventilating, or otherwise altering the space to dilute any atmospheric hazards. You’ll also need to ensure that authorized entrants are trained to deal with any lurking dangers, while continuously communicating with an attendant outside. Before slipping into your hard hat and overalls, remember to test and monitor the atmosphere.

Documentation and Compliance

Just like a boat requires a sail, an anchor, and a rudder for successful navigation, a complete confined space protocol needs a written program, a solid training curriculum, and an audit regimen. Daily safety logs, updated procedures when hazards change, and regular compliance checks create a robust system, giving your safety measures the edge and making them worth several pounds of cure.

Best Practices for Confined Space Safety

A workplace’s safety culture is not unlike a building’s foundation – it must be sturdy for the structure to stand. From routine training and drills to in-depth hazard communication plans, every brick adds up. Remember to keep pace with technology – consider digital checklists, remote atmospheric monitoring, and modern compliance management systems. Additionally, a platform for reporting near misses and unsafe conditions can prove invaluable, often serving as the canary in the coal mine.

Emergency Response Procedures

In the event of an emergency during confined space operations – such as an unexpected flood of water or a cave-in, your emergency response drills will prove their worth. Regular drills and training sessions help ensure that exposed personnel know their roles, and that communication protocols proceed as planned. Following an incident, a post-incident review offers a look in the rear-view mirror – what happened, why, and how can we improve?

Every workspace is unique, and therefore every confined space has its own story to tell. Proper identification, understanding potential hazards, and knowing how and when to get a permit will ensure your tale doesn’t become a tragedy. With the correct safeguards in place, knowledge of confined space safety can be the agent of safety that turns the tide.